Active Window

Smart Building Automation System with CAN Bus Communication

Project Impact & Significance

Climate Challenge

Global electricity consumption per capita rose 2.6x from 1971-2014 (1,200 to 3,132 kWh), with 89.6% from non-renewable sources. Building automation can significantly reduce operational costs and carbon emissions through improved energy efficiency.

Market Problem

Current solutions are manufacturer-specific and expensive (Honeywell, Siemens), or use unreliable wireless communication with monthly subscription fees. Limited adoption due to high costs and proprietary lock-in.

Our Solution

Open-source, low-cost system using reliable wired CAN bus communication. Designed for widespread adoption to create non-negligible impact on residential greenhouse gas emissions through affordable smart building automation.

Project Overview

Problem Statement

Building automation systems can help reduce operational costs and carbon emissions by improving energy efficiency. However, many current solutions are manufacturer specific and expensive, making widespread adoption difficult.

Our Solution

Our project aims to assist the non-profit Manhattan-2 company develop "electrical and communications standards that define how devices interconnect within the building of the future."

- •Facilitate the development of an open-source software framework (Building Bus) to enable easy smart home device development

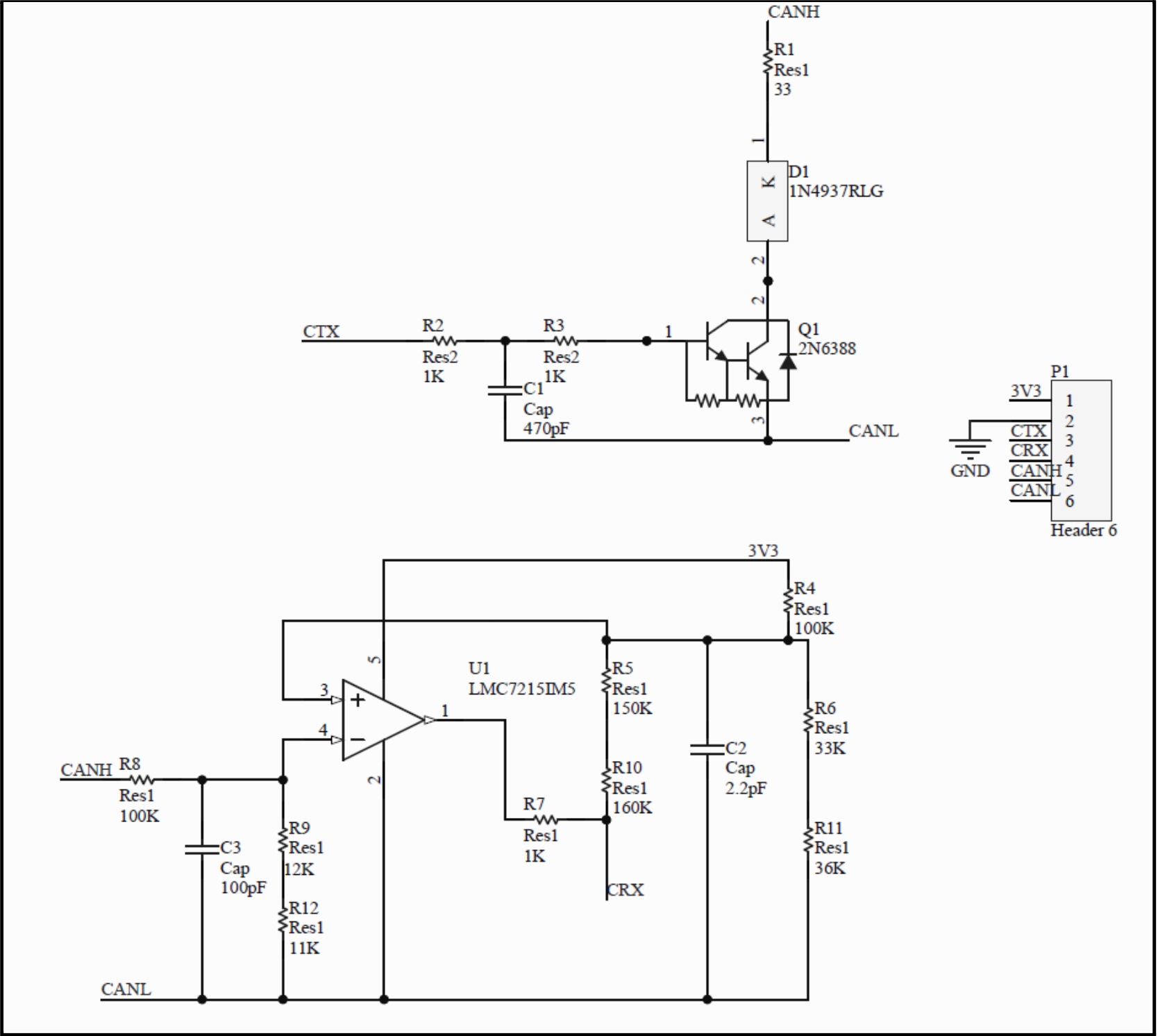

- •Develop a new CAN transceiver circuit that emphasizes smart building network priorities, particularly higher-reliability and lower operational power

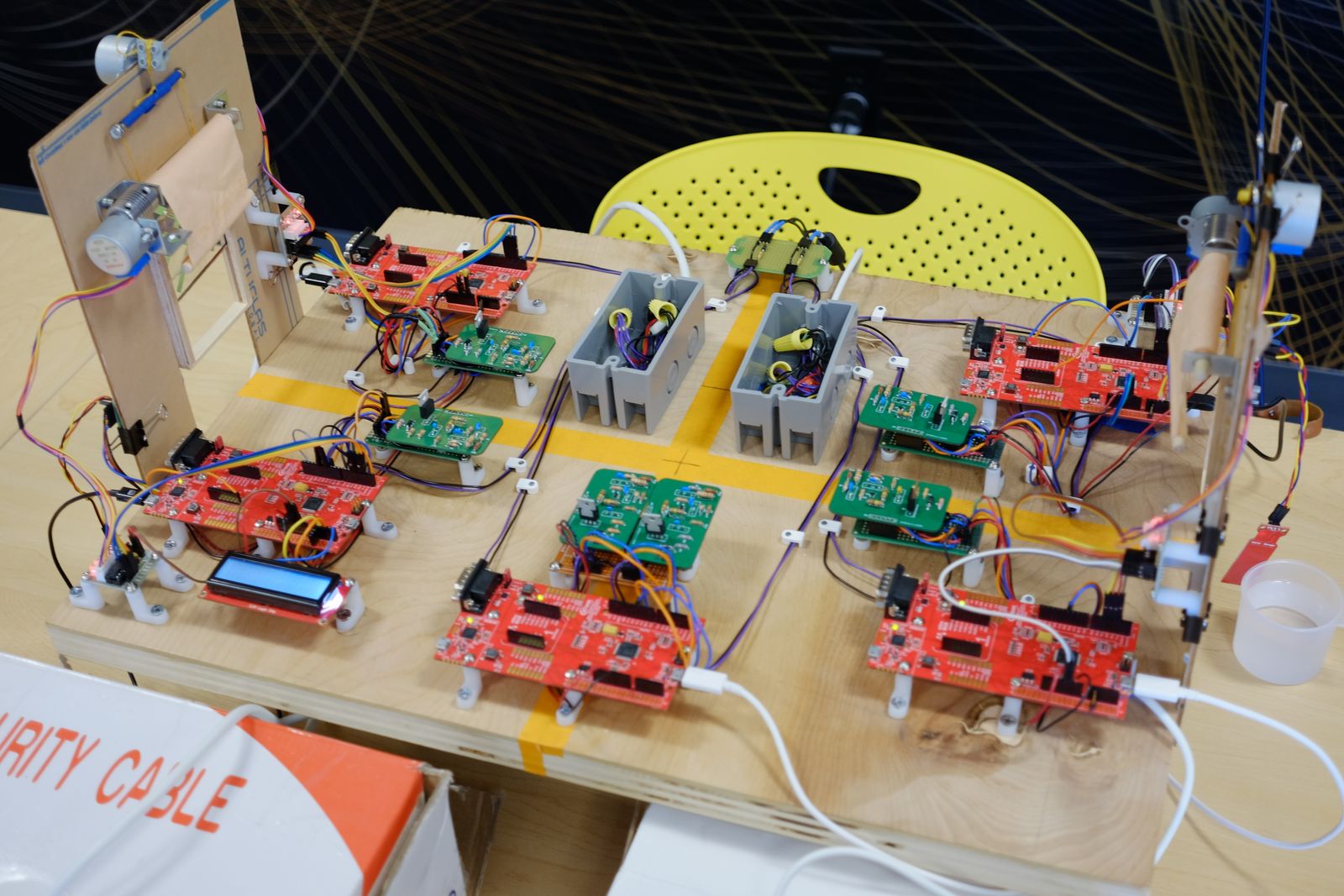

Active Window project team with prototype setup

System Specifications

Networking Software

- ✓Supports communication from master controller to devices

- ✓Support various function calls and commands

- ✓Supports tree networking topology

- ✓Processor sleeps when not processing network packets

- ✓Identify each device with serial number/address

- ✓Uses CAN bus communication protocol

- ✓Uses only C/C++

Physical Layer

- ✓Provides a maximum of 5mA of power to device transmitters

- ✓Defines a logic 1 and logic 0

- ✓Supports CAN bus (Wire-AND)

- ✓No damage to devices in event of accidental short

System Architecture & Implementation

Distributed Network Design

The prototype demonstrates a dual-network architecture with five XMC4200 boards. The system is divided into left and right networks, each powered by 16V and housed in electrical boxes for safety and organization.

A central repeater board with dual PCB transceivers enables message forwarding between networks, creating seamless communication across the entire system while maintaining network isolation for fault tolerance.

Smart Sensor Integration

Three sensor types provide comprehensive environmental monitoring: TMP36 temperature sensors(calibrated against reference thermometer), photoresistors for light detection, and water level sensors for rain detection.

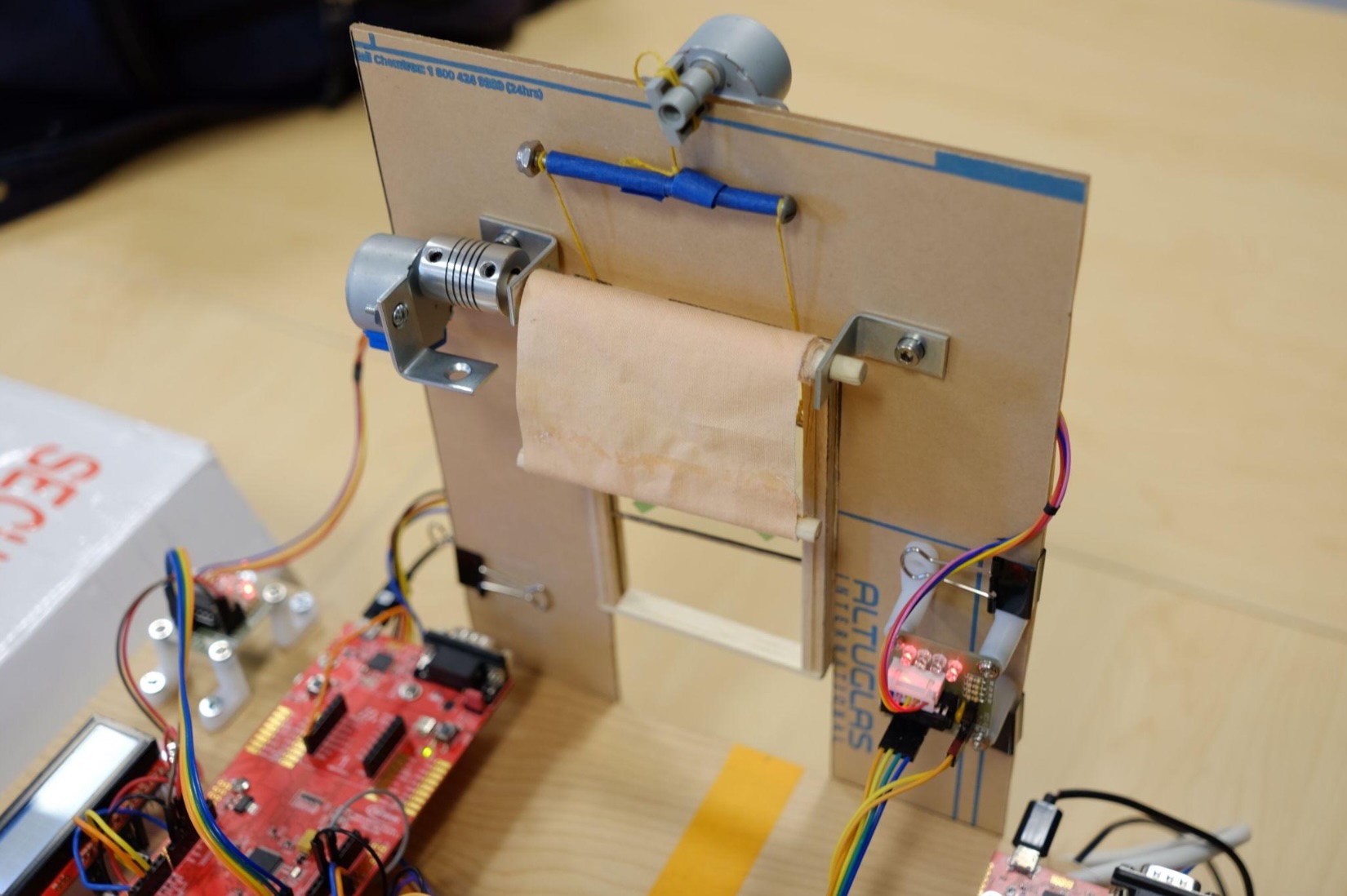

28BYJ-48 stepper motors with ULN2003 drivers provide precise window and blind control with excellent holding torque for safety. Custom-built 6"x4" balsa wood windows with plexiglass and cloth blinds demonstrate real-world applications.

Interrupt-Driven Real-Time System

The software architecture uses interrupt-driven programming for optimal performance. Timer interrupts fire every 10ms for sensor readings, while network interrupts handle incoming CAN messages. This approach minimizes CPU overhead and ensures responsive system behavior across all distributed nodes.

Live System Demonstration

System Demo Video

Watch the complete Active Window system in action, demonstrating automated window control, sensor integration, and CAN bus communication between XMC4200 boards.

Technical Achievements & Performance

Requirements Achievement Status

Fully Achieved

- ✅ Logic Definition - Clear logic 1 and 0 states

- ✅ CAN Bus Support - Hardware-accelerated communication

- ✅ Tree Topology - Flexible network architecture

- ✅ Broadcast Messaging - Network-wide communication

- ✅ Reliability - Zero dropped packets achieved

Partially Met

- ⚠️ Power Consumption - <5mA target limited by dev board overhead

- ⚠️ Point-to-Point Messaging - Broadcast implemented, P2P pending

Technical Design & Implementation

Physical Implementation

Prototype Setup

Complete prototype setup with XMC4200 boards and sensors

Window Assembly

Motorized window assembly demonstrating automated control system

System Architecture

System Diagram

Overall system architecture showing component interactions and data flow

CAN Transceiver Circuit

Custom CAN transceiver circuit design for smart building networks

PCB Design & Hardware

PCB Schematic Design

Custom PCB Schematic optimized for CAN bus communication and power efficiency

PCB Layout Design

Custom PCB layout optimized for CAN bus communication and power efficiency

Performance Testing & Hardware Specifications

Frequency Analysis & Response Testing

Network Performance Metrics

- Message Transmission Range:1000+ feet

- Network Response Time:10ms average

- Packet Loss Rate:0%

- Bus Voltage:16V stable

Sensor Calibration Results

- Temperature Accuracy:±1°C (calibrated)

- Light Sensor Range:0-1024 ADC values

- Stepper Motor Precision:2048 steps/revolution

- System Update Frequency:100Hz (10ms interrupts)

Custom PCB Design & Implementation

Developed a custom PCB design that serves as the foundation for our distributed network architecture. The board features an integrated CAN transceiver, power regulation circuitry, and standardized sensor/actuator interfaces.

Key Components

- • XMC4200 microcontroller

- • MCP2551 CAN transceiver

- • LM7805 voltage regulator

- • Status LED indicators

- • Screw terminal blocks

Design Features

- • Isolated power domains

- • ESD protection circuits

- • Modular sensor interfaces

- • Debug header access

- • Compact form factor

Technical Specs

Our Creative Team

UMass Senior Design Project Team 15

Michael Chan

CAN Protocol & Power Systems Engineer

EE

CAN protocol implementation, power distribution analysis, requirements validation, component sourcing

Dingbang Chen

Firmware & Mechanical Integration Engineer

CompE

Firmware development, stepper motor integration, mechanical calibration

Nathan Johnson

Network Architecture & Software Engineer

CompE

Network topology design, interrupt handling, firmware development, performance testing

Tien Shen

Hardware Lead & Project Coordinator

CompE

Sensor integration & algorithms, PCB design, window assembly fabrication, team coordination

Collaborative Achievement Highlights

Hardware Excellence

- • Custom PCB design from concept to manufacturing

- • Robust power distribution with 16V bus system

- • Modular sensor interfaces for scalability

- • Professional-grade component selection and sourcing

Software Innovation

- • Real-time interrupt-driven architecture

- • Reliable CAN bus protocol implementation

- • Advanced sensor calibration algorithms

- • Zero packet loss network performance